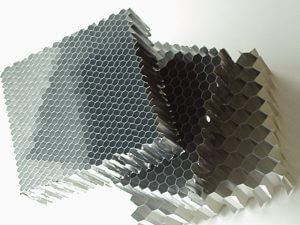

Honeycomb Block Stacker

Encocam produce high performance Honeycomb for use in aircraft, train and automotive applications. The material is light weight and has good anergy absorbing properties.

The honeycomb is manufactured by stacking sheets of material which have glue lines pre-printed on them. The relationship between the glues lines is critical, because the stack is later baked and stretched into the honeycomb form. Any error in the sheet placement results in a block with the wrong geometry and therefore the wrong mechanical properties.

I wrote the software to control the 10 axis machine which cuts and stacks the honeycomb material. A Lenze motion controller and HMI were used for the motion control and logic. The servo index axis uses a high speed sensor to register the glue lines in the stack.

A serial number on the job sheet is read with a barcode reader connected to Encocam's networked PC. To minimise operator intervention, I wrote a C# application to interrogate Encocam's database and send all the product parameters to the motion controller.

A serial number on the job sheet is read with a barcode reader connected to Encocam's networked PC. To minimise operator intervention, I wrote a C# application to interrogate Encocam's database and send all the product parameters to the motion controller.

Darryl's knowledge of automation is amazing. He took all our various drive, pneumatic and control systems for our honeycomb stacker and merged them into a functional automated machine for us. We have developed a great partnership with Darryl and will look to him to helping us with future projects.

Geoff Whitfield - Project Engineering Manager